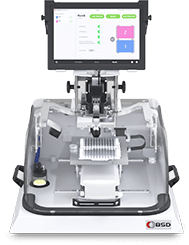

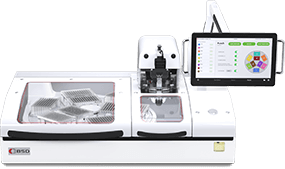

Products

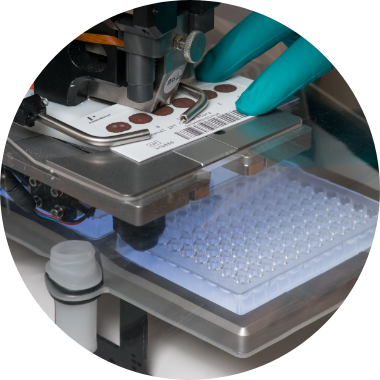

BSD products improve efficiency and productivity of sample preparation to enhance laboratory workflows. This is achieved through minimization of variability and human error, augmenting traceability and expanding process documentation. We aim to make routine and laborious sample preparation processes easier and safer for people who use our products.

Why Our Products?

Benefits

BSD punchers provide superior time-proven reliability and longevity.

We offer comprehensive support for our products to keep instruments working day-in day-out.

BSD instruments are designed for flexibility.

A wide range of applicability demands system flexibility. BSD maintains keen attention to the needs of our customers to ensure capability and performance.

We embrace the human elements.

Our core values, design philosophies and customer support are centered on how our customers work and interact.